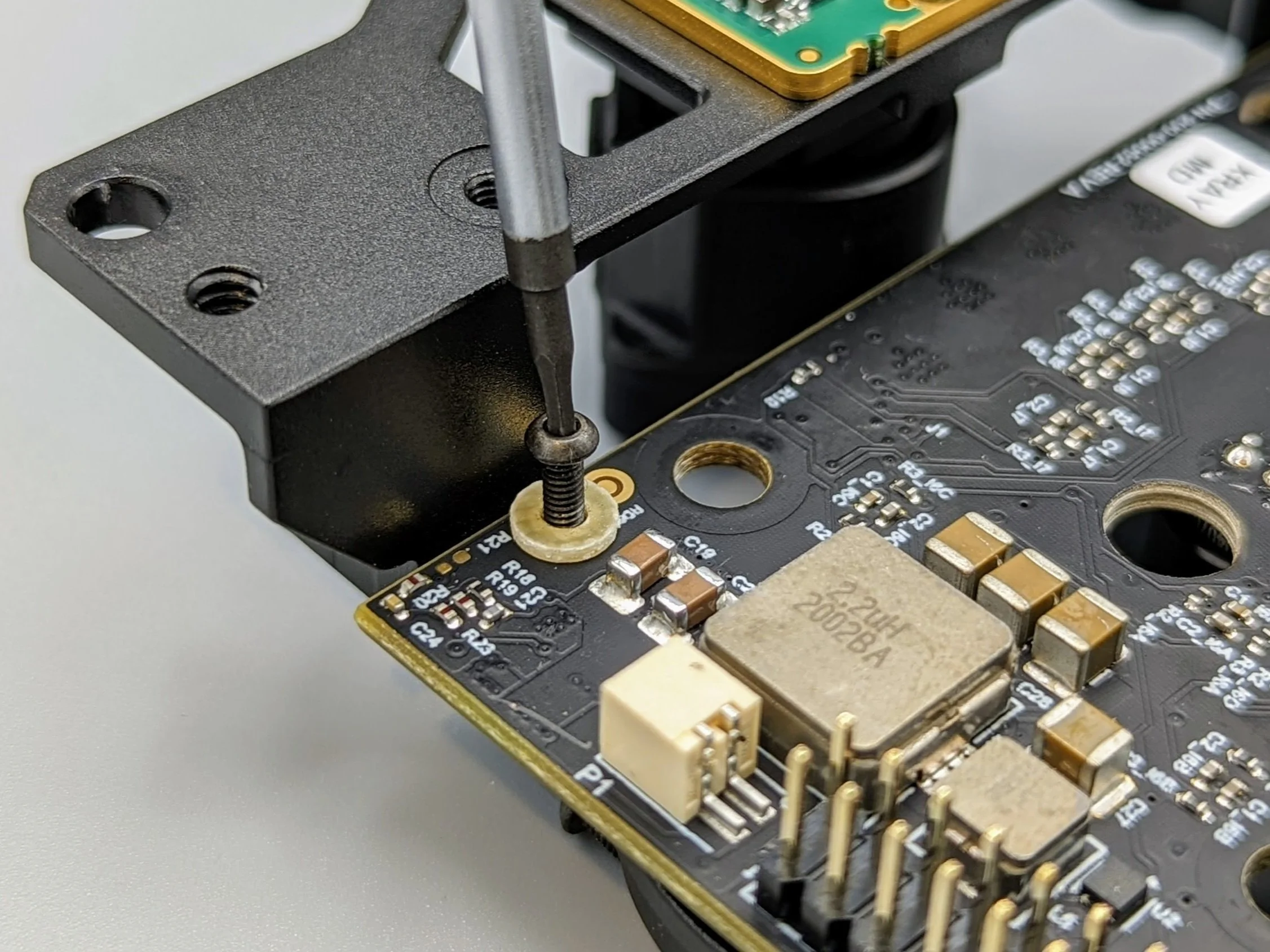

From concept development to FDA Class II approval

Beginning with industrial design research and ending with a fully realized opto-mechanical product FDA approved for advanced wound care. Cofab led the mechanical product design and development in parallel with electrical and software development teams over a two year span.

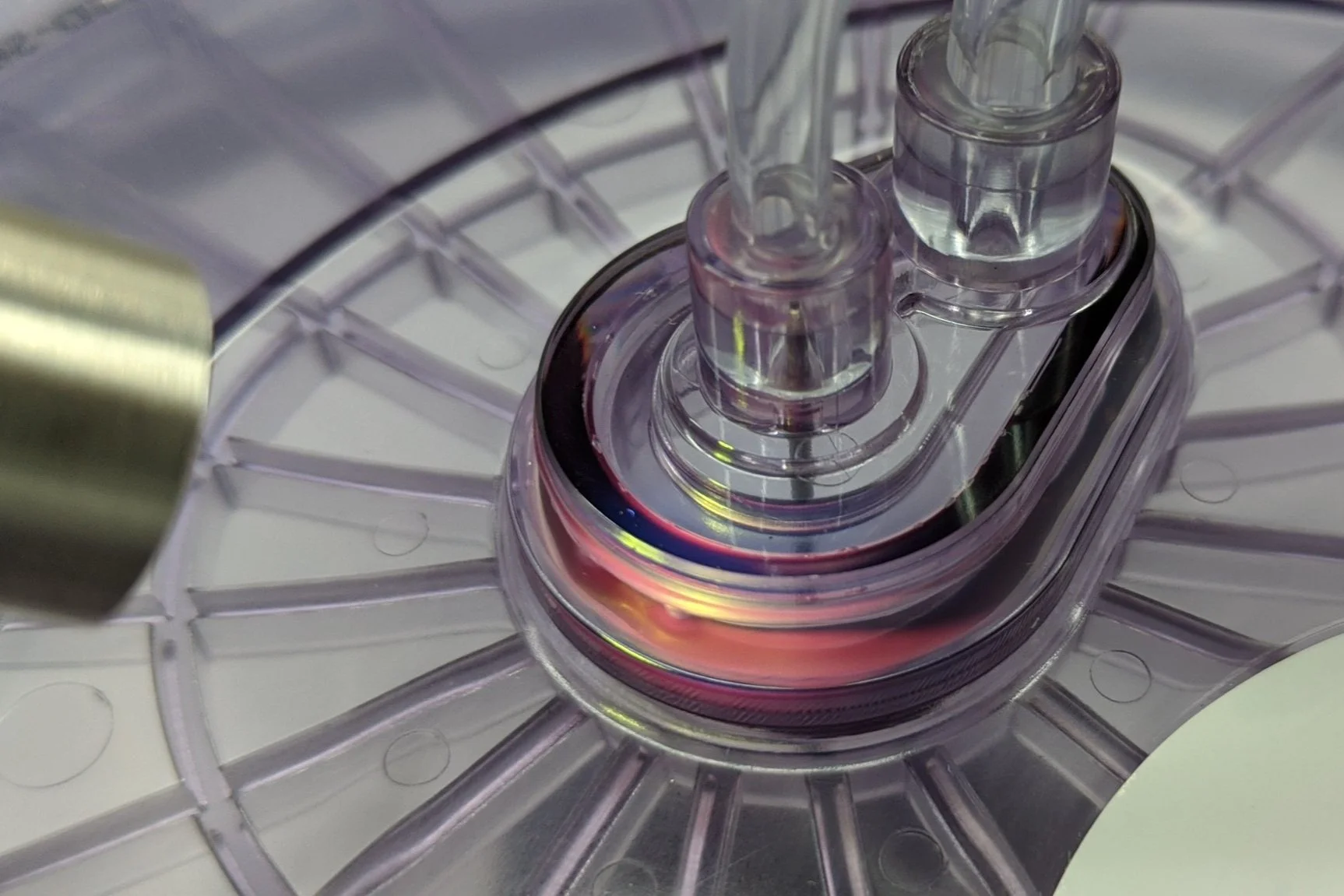

Product design and DFX from the start

Transitioning proven blood plasma science from the lab into the field by designing a novel medical grade processing cartridge from the ground up. Releasing parts for injection molding while simultaneously developing the automation equipment for precise, scalable manufacturing.

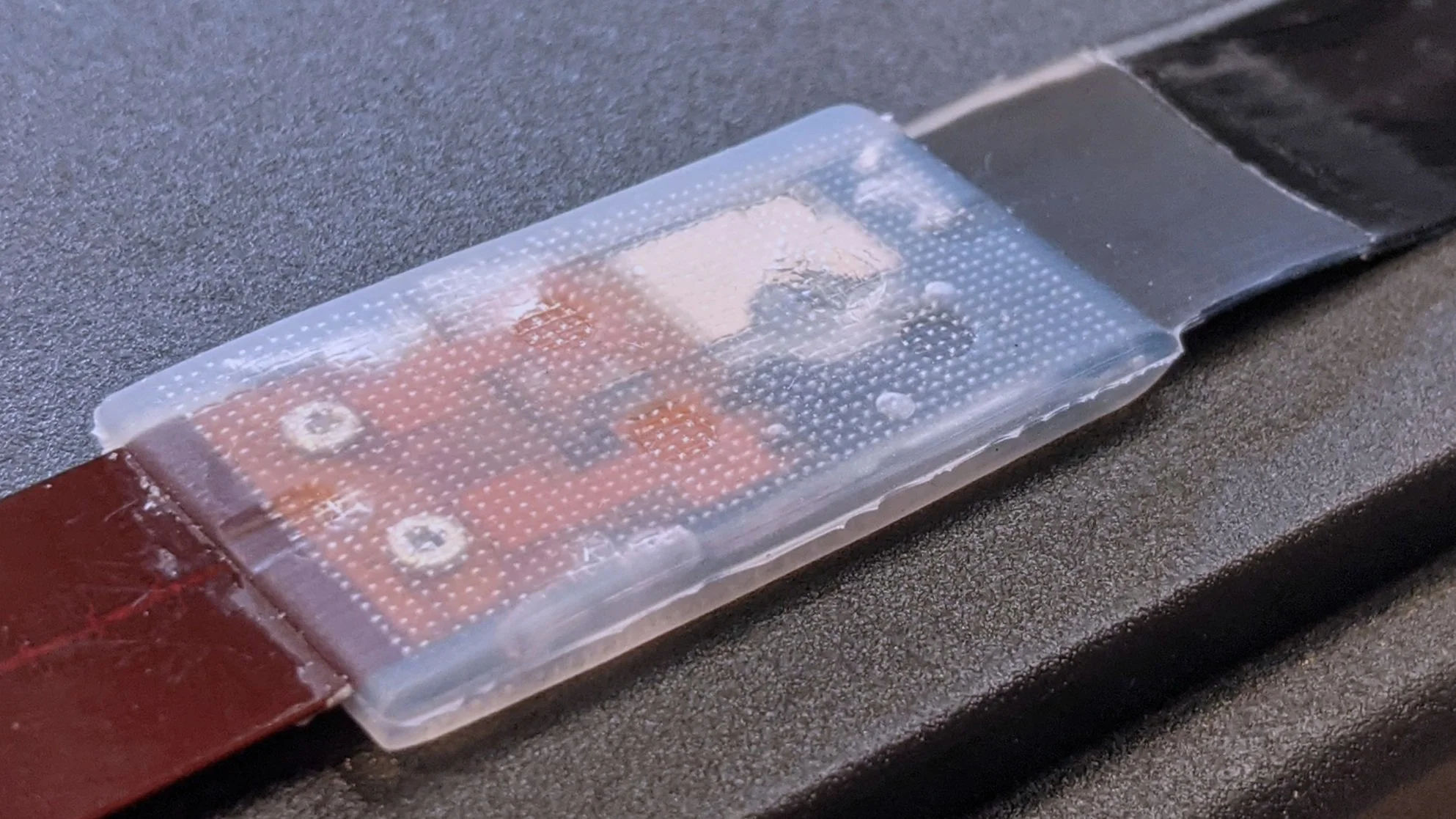

Lifesaving wearable device design

Unique product requirements for a wearable lifesaving cardiac system drove device design with novel thin film fluidic circuits. By combining specialized materials, new precision manufacturing techniques and years of R&D testing, a next gen wearable cardio-defibrillator was brought to market as a Class III medical device.

Rapid full cycle product development

Research, design, engineering, and manufacturing implementation of a durable, modular, high performance silicone face-fitting respirator in 6 months. Open Standard Industries (OSI) spun off from Cofab as a separate company and the product was proven to exceed NIOSH performance specifications.

Advanced tooling and process development

Intensive process and product R&D to innovate on tooling strategies for thin-film face-fitting wearable CNEP device. This novel implementation of single-tool post-vacuum-forming impulse welding led to a new method of 3D plastic joinery and associated intellectual property.

Balancing value engineering and user experience

Design for cost reduction of a legacy assembly while maintaining core functionality and improving both the patient and provider experience. Knowledge of existing manufacturing and assembly process challenges provided the opportunity to dive into industrial design, soft goods & design engineering to propose optimized solutions for the client with production quality prototypes.

Generational technology improvement

Enhance the performance of an elastomeric sensor system integrated into a wearable device, including rapid turn in-house silicone molding to drive iteration. Core component in a high performance athletic garment for advanced biometric monitoring.